In Vietnam’s industrial landscape, every machine component affects the performance of an entire production line. Finding a Vietnamese piston manufacturer that meets international technical standards locally is no easy task. Relying on foreign suppliers often brings cost burdens, timeline risks, and communication challenges in technical matters.

Understanding these pain points, Metal Solutions was founded with a clear vision: to become a leading domestic manufacturer of machine parts—especially pistons. We don’t just deliver a component; we provide a comprehensive solution. This is not only a promise of quality but a key answer to the supply chain dilemma many businesses face.

Why Choosing a Vietnamese Piston Manufacturer is a Strategic Decision

Partnering with a local piston manufacturer like Metal Solutions offers undeniable advantages:

Cost Optimization: Eliminate international shipping fees, import taxes, and trade barriers.

Logistics Control: Fast and flexible delivery timelines, minimizing disruptions in your production line.

Instant Technical Support: Work directly with our engineers for product customization and real-time troubleshooting.

Market Insight: We understand the unique operational conditions in Vietnam and provide material and design recommendations accordingly.

Metal Solutions – The Manufacturing Edge of a Professional Piston Producer

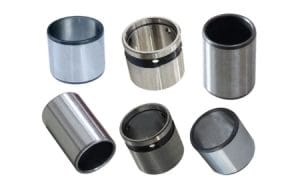

Our reputation is built on production excellence and product quality. Metal Solutions pistons are designed for top-tier performance, with superior technical characteristics:

Ultra Wear-Resistant Surface: Special machining processes ensure high resistance to friction and pressure for consistent operation.

Exceptional Longevity: Premium materials and precise manufacturing extend piston life and reduce maintenance costs.

Chemical & Heat Resistance: Our pistons perform reliably in the harshest industrial environments, from chemical plants to high-temperature furnaces.

Ultra-Smooth Surface Finish: A mirror-like surface minimizes friction, enhances seal tightness in hydraulic and pneumatic systems, and boosts engine efficiency.

Low Thermal Expansion: Controlled expansion rates ensure the piston maintains its dimensions and tolerances even under sudden temperature changes.

Diverse Material Options: From alloy steels and high-strength cast iron to specialized aluminum alloys, we tailor material selection to your application needs.

Precision Manufacturing System

We invest in cutting-edge CNC machinery, capable of producing complex piston geometries with the strictest tolerances. Every product undergoes a multi-step quality control process to guarantee uniformity and perfection.

Experienced Engineering Team

Our QA/QC system is operated by a dedicated team of engineers who monitor quality from raw materials to finished products. Every batch of material is thoroughly inspected before entering production. During machining, all technical parameters are closely tracked to ensure each piston complies with the design and original technical specs.

Before delivery, each piston is comprehensively tested for size, hardness, concentricity, and coating adhesion. This multi-layered closed-loop process ensures our pistons are not only durable and precise but also ready for immediate deployment.

Diverse Piston Product Lines for Multiple Industries

Our core strength lies in hydraulic pistons, where demands for precision, sealing, and pressure resistance are highest. We proudly provide piston solutions for industrial automation systems.

Additionally, Metal Solutions specializes in custom piston production. We can design and manufacture pistons based on technical drawings or physical samples to meet the exact requirements of each unique project.

Case Study: Metal Solutions – Strategic Partner of Hòa Phát Group

Trust is earned through action. Our long-term strategic partnership with Hòa Phát Group—one of Vietnam’s top industrial conglomerates—is a clear testament to our capabilities.

Background: Hòa Phát’s production lines require hydraulic pistons to operate 24/7 under extreme temperatures, dust, and pressure.

Challenge: They needed a local supplier capable of meeting strict technical standards while ensuring a stable supply chain.

Solution & Results: Metal Solutions delivered high-durability pistons with longer life cycles than previous imports. Our consistent quality and responsive technical support made us a trusted partner, with repeat orders over several years.

Latest Milestone: In 2025, Hòa Phát placed an additional order for 75+ large-scale hydraulic pistons for a production line expansion—raising the total number of pistons supplied to them to several hundred.

This success story is a rock-solid testament to the quality and commitment Metal Solutions brings to every client.

Conclusion

As Vietnam’s industry faces growing challenges in sourcing high-quality local components, Metal Solutions stands out as a reliable answer.

We manufacture world-class pistons that help businesses lower costs and avoid delays caused by overseas dependency.

Metal Solutions proudly serves as your strategic partner—delivering consistent quality and performance for production lines across Vietnam.

📞 Contact us at (028) 6265 8152 or visit metalsol.vn for more details.